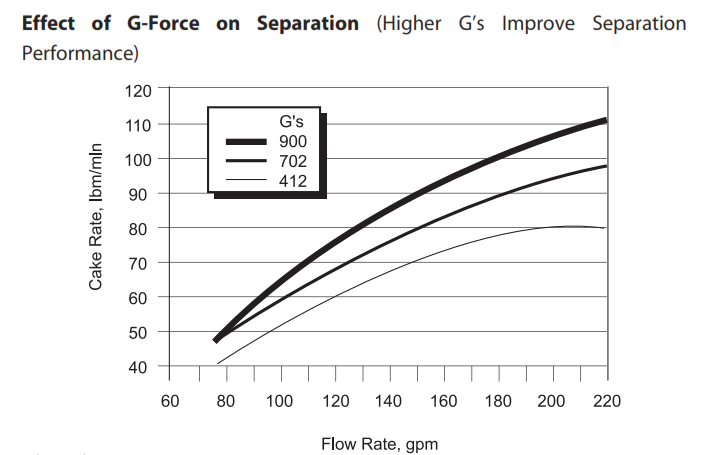

According to Stokes Law, particle setting velocity is proportional to G-force. Since G-force increases with the square of bowl RPM, it is an important parameter of decanting centrifuge performance. G-force also increases linearly with bowl diameter. Figure 1 shows how solids removal efï¬ciency improves with increasing G-force. For a given particle size and fluid properties, there is a minimum G-force necessary to invoke settling. Although high G-force is desirable, the cost is proportional to the cube of the bowl rpm and there are similar economic limitations on bowl diameter as well. Thus, the required G- force must be obtained from a practical combination of speed and diameter. Most oilï¬eld decanting centrifuges have bowl dimensions from 14 to 28 inches in diameter and lengths from 30 to 55 in. Rotational speeds range from 1000 rpm to 4000 rpm, depending on the application. The more expensive, high “G†machines can provide up to 3,000 G’s.

Effect of G-Force on Separation (Higher G's Improve Separation Performance)

Note: however, that increasing G-force eventually reduces solids conveyance capacity due to torque limitations. As G-force increases, more solids are settled in the bowl and they adhere more tightly. More conveyor or torque is required to move the solids out. Once the torque limitations of the machine are reached, conveyance ceases.

G-Force for a Decanting centrifuges:

G’s = RPM2 x .0000142 x Diameter of Bowl (in inches)

High G-force decanting centrifuges are available from GN Solids Control.

- Details

-

Published: 28 December 2013