- Details

-

Published: 19 October 2025

This October, the global mining sector will gather in Beijing for the 21st China Coal & Mining Expo (CCME 2025), a top-tier event focused on propelling advancements in coal and mineral extraction technologies.

Event Overview

Set to run from October 28 to 31, 2025, at the Capital International Convention and Exhibition Center in Shunyi, Beijing, CCME 2025 is expected to draw a diverse range of exhibitors. These include prominent domestic and international manufacturers, technology suppliers, and industry specialists. Over the course of four days, the exhibition will zero in on sustainable mining practices, automation, and equipment innovation, providing attendees with a gateway to the latest and most effective coal mining solutions.

GN Separation's Participation

GN Separation is among the exhibitors and will be stationed at Booth A4601. The company is set to display a range of equipment aimed at tackling key issues in coal preparation, tailings management, and underground mining operations.

1. Large Flip-Flow Vibrating Screen

The centerpiece of GN Separation's exhibit will be its Large Flip-Flow Vibrating Screen, a groundbreaking screening technology tailored for fine-grained and sticky materials. Traditional vibrating screens often encounter problems like clogging and inefficient separation when handling fine coal, wet ore, or materials rich in clay. GN's flip-flow design, however, breaks through these limitations. By integrating a flexible polyurethane screen surface with a double-mass near-resonance working principle, it prevents screen blinding and pegging, ensuring a steady throughput. In the realm of coal mining, this equipment proves especially valuable for pre-screening raw coal before the washing process, thereby easing the load on subsequent operations.

2. Tailing Dewatering Decanter Centrifuge

Tailings disposal stands as one of the most urgent environmental challenges in the mining industry. GN Separation's Tailing Dewatering Decanter offers an eco-friendly solution. It reduces the water content in mine waste, separating solids from liquids to produce a dry, stackable cake. This not only minimizes land use but also lowers the risk of leachate. In coal preparation plants, the decanter centrifuge facilitates the recycling of process water, cutting down on freshwater consumption. With a capacity of up to 100 cubic meters per hour, it is an ideal choice for mid-to-large-scale operations looking to enhance waste management while adhering to ESG (Environmental, Social, and Governance) standards.

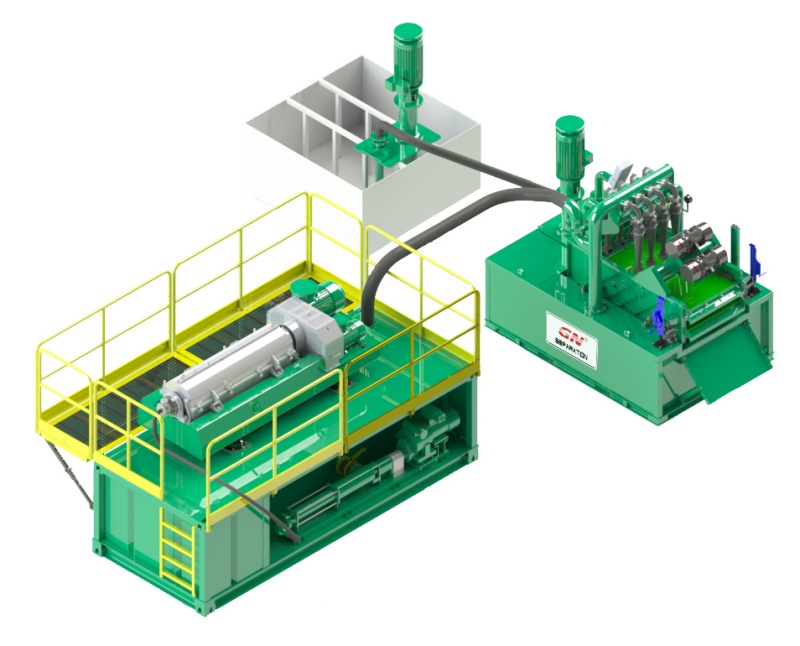

3. Underground Coal Sump Slurry Separation System

Underground mining environments present unique hurdles, such as limited space, water inflow, and the urgent need for efficient slurry handling. GN Separation's Underground Coal Sump Slurry Dewatering System addresses these challenges by integrating a compact decanter centrifuge with a pre-screening module. It treats the muddy water generated during roadway tunneling, coal extraction, and dust suppression. The system first separates coarse solids using a screening cyclone combination unit, and then transfers the slurry to a dewatering centrifuge for fine particle separation. This process eliminates the need for manual sump dredging, ensures smooth mine drainage, and supports safe, efficient, and eco-friendly mining practices. Typically designed in a modular fashion, the system is easy to transport, install, and relocate, enabling mobile use.

GN Separation: Leading the Way to a Sustainable Mining Future

With over ten years of experience in separation technologies, GN Separation has cemented its reputation as a reliable partner for mining companies across the globe. Its participation in CCME 2025 underscores its commitment to innovation and customer-focused design. Visitors to Booth A4601 will have the chance to interact with technical experts, witness live demonstrations, and explore customized solutions tailored to their specific operational requirements. We warmly invite you to visit GN at the expo.