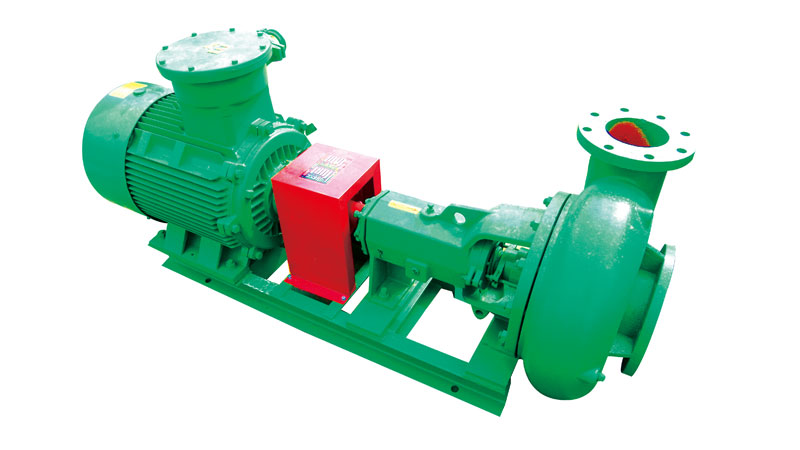

GN Solids Control makes different sizes of centrifugal pump to suits to different applications, like for mud mixing by working together with mixing hopper, to feeding for desander and desilter mud cleaner, to feed for decanter centrifuge, to be used as trip pump, charging pump, to work as transfer pump to here to there, and work as suction tank to suck drilling fluids from mud system and feed for mud pump for drilling activities.

Here are major centrifugal pump sizes made and sold by GN Solids Control: GNSB4×3, GNSB5×4, GNSB6×5, GNSB8×6. The 2 numbers here indicate the pump inlet and outlet sizes in inch, the bigger number standards for the suction pipe size, while the smaller number indicates the outlet pipe size. For centrifugal pump, the inlet size must be bigger than outlet pipe. Another important design to determine the pump performance is the diameter of the pump impellers. For the same pump size, the bigger size the pump impeller, the bigger flow it can handle. And the motor power must be accordance with the pump size (inlet size, output size and the impeller size).

GN Solids Controlpump design and all its spare parts are fully interchangeable with a traditional famous pump model: Mission Magnum. In this case, clients can easy source spare parts and replace GN pumps in their existing systems.

There are so many pump manufacturer, while GN Solids Pump performance better than others’? Below are some advantages of GN Solids Control centrifugal pump:

1) Thick, Strong Concentric casing provides extended life over conventional volute designs. The Concentric design minimizes turbulence and abrasive wear.

2) GN Solids Control pump casings are all made from hard ductile iron alloy, increased abrasion resistant capability compared to competitors’ pumps.

3) Wide open-vane impeller creates lower axial thrust for improved bearing life.

4) Anti-loosening impeller lock bolt to eliminate pump damage in case of improper motor hook-up.

5) The skid for supporting pump and motor is made from casting instead of welding to provide reliable operation and less vibration in a result to extend the pump and motor life.

GN Solids Control owns the full production line for big sizes decanter centrifuge manufacturing. GN Solids Control utilize the same production line as centrifuge to make centrifugal pump, which ensure a reliable and excellent performance.

- Details

-

Published: 24 March 2018

As one of the major liquid and solids separation centrifuge manufacturer, GN Solids Control exported many dewatering centrifuge systems to worldwide market, like Canada, British, Singapore, UAE… GN dewatering centrifuge system can be used in oil field and non-oil field.

GN Solids Control exported many big bowl dewatering centrifuge systems to Singapore for construction field waste water treatment. It can be used to treat and recycle waste water from horizontal directional drilling, from piling project, from micro tunneling projects, from dredge slurry separation projects, or from other pipeline and underground activities.

Recently, GN engineer come back from Singapore and finished the commissioning and training works of a new dewatering centrifuge system there. Now the waste water treatment system is running well, clients are happy with it.

The water centrifuge for Singapore client is very similar to other dewatering centrifuges sold there before. It includes below processing equipment:

1) Big bowl decanter centrifuge GNLW553C-VFD. It is a 22inch big bowl decanter centrifuges widely used for fine solids separation, for drilling mud separation and waste water treatment.

2) An automatically power chemical mixing and dosing system. The chemical dosing system will be used before the waste water feeds to the centrifuge bowl for flocculation.

3) As the construction waste water treatment is mostly took at near the city or in the city. There I a strict limitation on space. GN Solids Control fixed Both the automatically power chemical mixing and dosing system and the 22 inch big bowl centrifuge into containers respectively. And the 2 containers can be laid at 2 layers. The big bowl decanter centrifuge container will be put on top of the chemical dosing system container. It is easy for movement and can saves space.

The centrifuge dewatering system is used after the slurry separation system. The slurry separation system will remove most of the big size solids in liquid, to reduce the mud weight and the solids contents, and to make the waste water qualified for centrifuge separation. GN Solids Control can also offer the slurry separation system (C/W with shale shaker, hydro cyclone separator, feeding pumps, mud tank system, lighting system, electrical control system).

- Details

-

Published: 17 March 2018

This week, a full set of containerized drilling waste cuttings treatment system and some mud treatment shale shakers are ready for shipment to a Russia customer. Every year, GN Solids Control exported many complete sets containerized cuttings drying systems to worldwide market, especially for Russia. As Russia market is very cold. More of half time of a year is frozen weather. It request all equipment and system for Russia market should be good at keeping warming at frozen weather, many time, it may under 50 C degree.

In order to keep warm and protect the equipment well, GN Solids Control put the drill cutting treatment equipment into the container, and there will be warming system all around the container.

The containerized cuttings drying system including a set of vertical cuttings dryer, a set of decanter centrifuge. A transfer tank with transfer pump is located between the vertical cuttings dryer and the decanter centrifuges.

As clients said, there are many vertical cuttings dryer brand in the market, GN Solids Control is the best. GN Solids Control makes the best vertical cuttings dryer among all dryers brand they used. And they will only buy drilling waste management equipment from GN Solids Control.

Russia is an important market for GN Solids Control, especially in the recent year. GN Solids Control develops well and fast in Russia market. As GN main products are drilling waste management treatment equipment, like Vertical cuttings dryer, high G dryer, high speed decanter centrifuge, screw conveyors, dewater unit, etc…

Middle east and Africa is another important market of GN Solids Control. Unlike Russia market, Middle east and Africa are most very hot reason, may time, it will up to + 55 C degrees. The equipment, especially the VFD centrifuge must be equipped with excellent cooling system to ensure a stable performance. GN Solids Control did it well. All job site cases proved that, GN Solids Control equipment can suit for -50 C degree to + 55C degree to cover the big temperature range.

- Details

-

Published: 12 March 2018

The Vertical Cuttings Dryer (V.C.D.) is used to pre-treat oil base cuttings and reduce the oil content (OOC: Oil on cuttings) to 3- 5%. In many countries, sands or cuttings with less than 5% or 8% OOC (Oil on Cuttings) is allowed to be discharged. The Vertical Cuttings Dryer (V.C.D.) can also be used to pre-treat the sludge oil.

Many customers cannot tell the difference of vertical cuttings dryer and decanter centrifuge for waste management application. They do not know what is the real difference between decanter centrifuge and VCD (vertical cuttings dryer).

Decanter centrifuge and VCD (vertical cuttings dryer) have different applications and functions while treating the drilling cuttings or the oily sludge.

Vertical cuttings dryer can be used to treat the drill cutting from shale shaker, mud cleaner, desander, and desilter. VCD cannot be used to treat cuttings from decanter centrifuges. As the solids from decanter centrifuges is too fine to remove. They will go through the screen opening of the VCD.

Some clients may ask what is the size and maximum size for screen to avoid the sludge to go through the VCD directly.

There are 3 sizes screen for VCD: 0.25 /0.35/0.5mm. All solids bigger than the screen opening will be removed by VCD, while smaller size particles than the screen opening go through the screen opening and is mixed together with the recovered liquid. 0.35mm is the most popular size.

As the solids smaller than VCD (vertical cuttings dryer) screen opening (0.25 /0.35/0.5mm) will go through the screen opening and together with the liquid. The recovered liquid fromVCD (vertical cuttings dryer)will be with a very high fine solids content. The mud weight is too heavy to be reused for drilling mud systems. Decanter centrifuge will be used afterVCD (vertical cuttings dryer)to remove fine solids and reduce the mud weight. After centrifuge, the liquid can go back to rig mud system for reuse.

- Details

-

Published: 02 March 2018

Screw conveyor system is widely used together with the vertical cuttings dryer system. The auger screw conveyer system can be used to feed cuttings to vertical cuttings dryer, and collection sands discharged from vertical cuttings dryer and then convey to cutting containers, trucks or other sand holding device.

GN Solids Control makes different sizes of screw conveyors to suits for different applications:

The auger diameter varies from 10 inch to 16 inch. There are 10 inch, 12 inch, 14 inch and 16 inch as standard size available from GN Solids Control.

Each size auger conveyor is with screw elements of length 12 ft for each section. The different sections of 12 ft. will be interchangeable. Transfer length can be 24 ft, 36 ft and 48 ft.

Screw conveyorsystem can be used together with other devices to suit for different applications.

Feeding type for Vertical cuttings dryer at rig site:

As the Vertical cuttings dryer is capable to treat the drilling cuttings discharged fromsolids control shale shaker, decander, desander or mud cleaner. It cannot be used to treat the soil discharged from decanter centrifuge. It is too fine to separate by theVG dryer screen basket.

In this case, at least 2 sets 36ft screw conveyer will be used in the rig side VG drying system:

Screw conveyor #1: It is in level to collect drill cuttings from solids control system

Screw conveyor #2: It should be inclined to collect cuttings transferred from #1 screw conveyor and convey to the VG dryer feeder hopper.

Screw conveyor to transfer drilling waste from waste pits or containers:

There should be a V-hopper on top of the screw conveyor to collection and buffer the drill cutting. And the screw conveyor is inclined to convey cuttings from the V-hopper to VG dryer.

However, the screw conveyor system is only suitable for the drilling cuttings with less liquid phase content. If the liquid content is high, screw conveyor cannot do. And it will cause leakage. Vacuum transfer pump will be used in case of the fluid content is high. It is a powerful 100% air driven pump suiting for a very wide range of applications.

- Details

-

Published: 22 February 2018

GNLW553C-VFD is a large bowl decanter centrifuge designed and made by the leading solids control manufacturer – GN Solids Control. The GNLW553C-VFD is a decanter centrifuge with 22 inch bowl size (>21†diameter). The 22 inch large bowl decanter centrifuge GNLW553C-VFD is equipped with Variable Frequency Drive system for a variable bowl speed can conveyor speed to suit for different applications.

GN Solids Control can offer complete centrifuge separation system with the 22 inch large bowl decanter centrifuge GNLW553C-VFD. The complete centrifuge system will be capable of running in continuous operation and suitable for different separation and application:

1) The 22 inch large bowl decanter centrifuge package GNLW553C-VFD is capable for LGS (low gravity separation) reduction with a high bowl speed.

2) The 22 inch large bowl decanter centrifuge package GNLW553C-VFD can be used for barite recovery in oil drilling mud system with a lower bowl speed.

3) The 22 inch large bowl decanter centrifuge package GNLW553C-VFD can be used to separate all types of Water Based Mud and Non Aqueous Based Mud with various properties dependent per the drilling activities.

4) GN 22 inch large bowl decanter centrifuge can separate drilling mud densities range between 8.34 to 13 ppg, the unit shall also be capable of processing fluid densities up to 21 ppg.

5) GN 22 inch large bowl decanter centrifuge package is capable of processing up to 15 tons/hour, with of volumetric capacity of up to 500 gpm with water

6) GNLW553 large bowl centrifuge is capable for continuous rotation between 0 to 3000 rpm, creating max. G force up tp 2770 G. And the scroll differential speed for convey material is 0 to 45rpm.

Wearing protection of GN 22 inch large bowl decanter centrifuge GNLW553

1) Feed Zone Wear Protection: Tungsten Carbide Wear Liners (360° type)

2) Conveyor Wear Protection: All length Tungsten Carbide hard surface paint

3) Bowl Solids Discharge Protection: Tungsten Carbide Wear Liners, plus Tungsten Carbide scrapers cleaning

4) Bowl Wear Protection: Ribs on inner diameter

- Details

-

Published: 14 February 2018