December is an amazing month for everybody. Firstly, it is Christmas day, and then the International new year is coming at the end of Dec. And after Dec., the biggest event - Chinese new year is on his way.

In order to thanks all GN clients’ support in the past years, and also to get more valuable feedback from Clients and operations, and to improve GN Solids Control products quality and services accordingly. GN Solids Control invite customers to fulfill and send back his Customer feedback form for what they want to say to GN company.

GN Solids Control prepared fancy gifts for all GN old clients and friends who do offer feedback to GN Solids Control. Anyone who purchased equipment from GN before, or with GN equipment running for their projects own the chance to get the fancy gifts. If you likes GN products, or you want GN Solids Control make any improvement, or even tell us what new equipment / technology you want GN can offer you in the near future, please write down on the Feedback Form, and send back to GN. To appreciate your time to fill your comments, GN Solids Control will post you a fancy gift.

Below is the way how to get GN gift for Christmas and New year.

Firstly, download GN Customer Feedback Form from GN website:

http://www.gnsolidscontrol.com/downloads/Customer-Feedback.docx

You fulfill the feedback form with your comments and suggestions regarding GN before sales services, after sales services, products quality, manufacturing time and etc…

Then you scan the form, and send the scan copy to GN Solids Control to This email address is being protected from spambots. You need JavaScript enabled to view it. ., or send to your main contact person in GN. Once GN company received your customer feedback form, GN will give you a confirmation, and post you a gift at the earliest time.

You only take 5 minutes, you can get a fancy gift from GN. Further more, your valuable words may help GN offer you better products and services in the future. So hurry up and take your action now.

- Details

-

Published: 23 December 2017

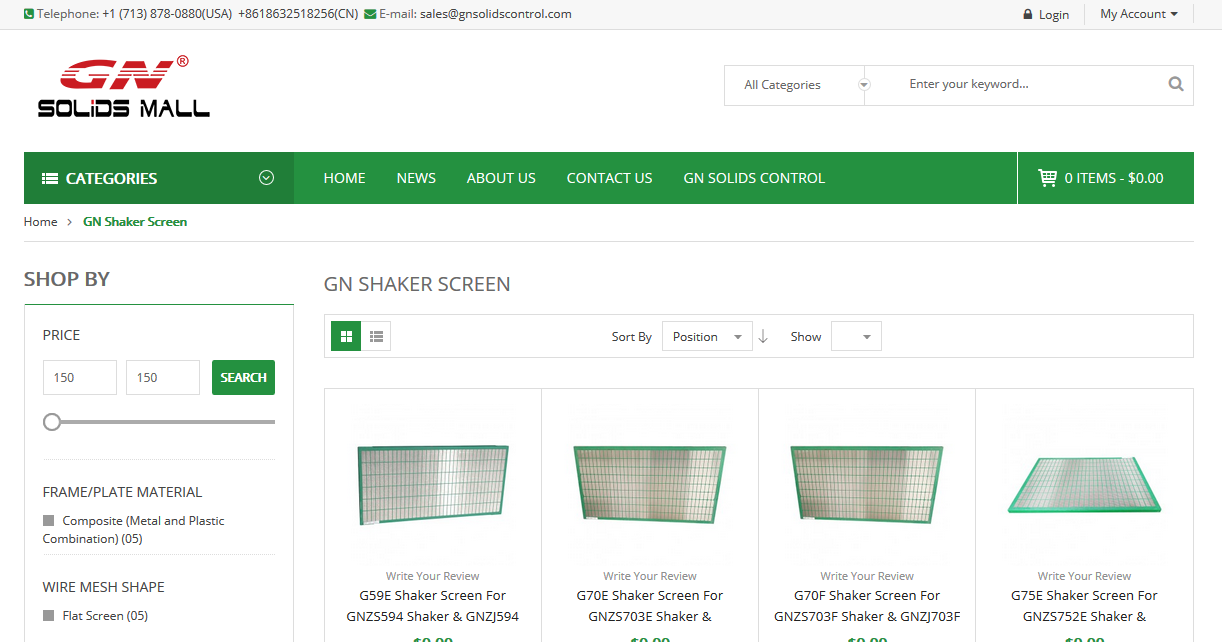

Replacement shakers screen is one of the most important products of GN Solids Control. In order to help customers easy to find the suitable replacement shaker screens they need, and help customers easy to place orders, especially to get screen samples for trial, recently, GN Solids Control published the shaker screen online shopping mall. Website ishttp://gnsolidsmall.com/

Clients can get self-help service 7 by 24 hours. Clients are easy to source and choose replacement screen models, they need. GN shaker screen online shopping mall is something like Amazon. Clients can choose what they need on line, place order on line, and also pay online by Visa card, Master card, PayPal, or other popular online payment access.

Why so many customers choose GN made replacement screens?

Firstly, GN Solids Control is also a famous shale shaker manufacturer. They know the shale shakers better than other shaker screen manufacturers. The knowledge on shale shakers helps GN know more about shaker screens, and how to improve the shaker screens performance and lifetime.

Secondly, as the old metal frame screen technology is not high efficiency, and the quality is not very reliable. GN Solids Control makes develops new technology on screen manufacturing. GN Solids Control makes all the popular shaker screen models from composite material. The new technology is also complied with government requirements for environment protection.

Thirdly, as a major solids control manufacturers, GN Solids Control has a very stable screen consumption for his own brand shale shakers and mud cleaners every year. It can support GN to invest much on screen production line. GN Solids Control owns his own injection machine for shaker screen frame manufacturing. The metal support within the composite frame is made by welding robot , the quality is much more reliable, and it is high efficiency. GN Solids Control can maker high quality replacement screen with good price and short leading time.

And finally, GN Solids Control owns API RP13C testing report for all its screen scope. The API RP13C report is the only provement that the API size and conductance are correct and complied with the standard. It is a very high cost and long time to get it. While GN Solids Control has the ability to do it.

- Details

-

Published: 18 December 2017

In the recent months, many customers showed great interests on GN made sludge transfer vacuum pump. They came to GN, contacted GN representatives, or sent inquires to ask for more information of GN made sludge transfer vacuum pump. They want to know if the vacuum pump for drilling cuttings transfer and oily sludge suction from deep waste pits. Here is a brief introduction of the GNSP Sludge Vacuum Pump.

GNSP Sludge Vacuum Pump is able to produce high vacuum up to 25â€HG (Mercury Column) for transfer liquid, drilling cuttings, sludge and solids.

You can visit GN Solids Control website to download the working video of the sludge vacuum pump and the technical brochures. Or contact GN sales teams for ask for support.

The GNSP Sludge Vacuum Pump is a 100% air driven vacuum pump. It is very safety for hazardous environment. The Sludge Vacuum Pump is without any rotation items inside the pump. It is suitable for long distance movement or easy for maintenance. With special structure design and powerful suction capability, The GNSP Sludge Vacuum Pump can be used at tough environmental for solids transfer,high working performance and less maintenance.

The GNSP Sludge Vacuum Pump is with max. suction depth 50m, and with max. discharge distance 1000m. The max. solids size allowable by GNSP Sludge Vacuum Pump is 17mm. The 1000 meter is the max. design discharge distance by water test. The typical max. distance depends on the transfer material. What is the max. distance you want to reach? We will let our engineer to calculate and double check.

As the GNSP Sludge Vacuum Pump is fully air driven, and the air consumption is 17m3/min. Before order, clients should check the available of the suitable air supply.

Below are some applications of the GNSP Sludge Vacuum Pump:

1) Suck and transfer waste mud and waste solids discharged from shale shaker, mud cleaner and centrifuge

2) Used for Drilling mud transfer

3) Used in waste pit cleaning, to suck the slop oil and waste water from tank cleaning

4) For Hazardous waste recovery and transfer

5) Oil sludge, tank bottoms residual removal and transfer

- Details

-

Published: 12 December 2017

GN Solids Control design and make portable tank cleaning system for oil field and industry tank cleaning. It is mainly designed for normal size and small size mud tank cleaning. GN automatic tank cleaning system is used together with a tank cleaning machine (a kind of wash gun).

The tank cleaning machine will suck clean water from butter tank inside the portable tank cleaning system, recovery the waste water from tank cleaning, and send back to buffer tank to clean tank again. The dirty water from washing tank will be recycled and reused in the tank cleaning process.

Tank cleaning machine is a kind of high pressure wash gun. It is imported from European. GN Solids Control can offer the whole package. Or recommend clients buy it directly from Europe for better price and shorter delivery time.

There will be a skip box to held sand and silt discharged from the cycling system. Clients can buy from GN, or prepare it locally.

All other items besides tank cleaning gun and skip box are included in the portable cleaning system.

Before washing the tank, operators should fulfill the butter tank inside the system with clean water. After that, they can use the recycled water for cleaning.

Pls see below the process description.

1) Centrifugal pump will pump clean water from Buffer tank and supply to cleaning machine to clean the dirty mud tank.

2) Vacuum Pump will suck dirty wash water from dirty mud tank , between dirty mud tank and vacuum pump, the strainer will filter coarse solids.

3) Vacuum Pump will supply dirty wash water to desilter for removal of solids.

4) Removed solids from desilter will drop to Air Pump and then pump to Skip box outside the system.

5) The overflow from desilter will drop to inclined plate clarifier (IPC) for removing settable solids.

6) The clean water from clarifier will overflow to buffer tank for reuse.

7) Air Pump will take the slurry from the clarifier to Skip.

- Details

-

Published: 01 December 2017

Recently, 2 sets of big bowl dewatering centrifuge unit with containerized chemical dosing system are dispatched from GN Solids Control. The chemical dosing dewatering centrifuge unit is for a TBM mud treatment project in Singapore. The dewatering centrifuge unit is not the first system order GN Solids Control got from Singapore. Before this system, GN Solid Control sold a complete set mud treatment and dewater unit. For that project, the client need to get clean water after separation, and then discharge to the river directly after separation

The new big bowl centrifuge dewatering unit is including following items:

1) 1 set of big bowl decanter centrifuge, the model is GNLW553C-VFD.

It is a 22 inch big bowl decanter centrifuge specially designed for waste water and other industry waste management. The big bowl centrifuge is with G force up to 2179G. The design max. speed of the big bowl centrifuge is 3000rpm, while the max. working speed is up to 2500rpm.

GN 22 inch (550mm) decanter centrifuge is widely used for different industry .It is the medium size centrifuge which has the normal capacity requirement for most of the applications. It is popular for drilling mud treatment, and also it can be used for industry waste water treatment, oil sludge treatment, mining water treatment, chemical industry and food industry separation.

2) A full set of containerized chemical dosing system, model GNDU2000.

It is a 20FT Dewatering Unit provides a process of chemically enhanced configuration to remove the fine solids less than 5 microns from the water based drilling fluids.

As it known that traditional solids control equipment like shale shaker, desander desilter, and decanter centrifuge will removes solids upper than 5 microns, for ultra fine particles which is less than 5 microns will build up in the drilling mud system. By utilizing the GNDU2000 Series 20FT dewatering unit, the ultrafine solids can be efficiently removed by the chemical dosing system and the big bowl decanter centrifuge.

- Details

-

Published: 28 November 2017

This week, 2 complete sets cuttings drying system will be dispatched for a Russia client.

The containerized drill cuttings drying system is with below features:

1) As the temperature is Russia is frozen in winter, and the winter time is very long compared with other countries. They request a better warm system of the drill cuttings treat system. All the cuttings drying and treatment equipment are mounted in a 40ft container for keep warming.

2) Russia is a country with vast territory. The containerized drilling cuttings drying system design is also convenient for movement. During international shipment, the containerized system can be fold up and shipped as a shipper owner container (SOC).

3) The container inside is modified with lighting system, and warming system.

The Containerized Drill cuttings drying and separation system is including below devices:

A) 1 set vertical cuttings dryer model GNCD930D. It is the fourth generation cuttings drying device launched by GN Solids Control. For other brand vertical cuttings dryer, it can only be used to treat oil base mud and cuttings. But GN patent design vertical cuttings dryer can be used to treat oil base mud and cuttings, as well as water based mud and cuttings. A German brand screw pump is equipped as flush pump of the vertical cuttings dryer.

B) A catch tank with agitator to hold the recovered drilling fluids from Vertical cuttings dryer

C) A set 10hp (7.5kw) screw pump to feeding for the decanter centrifuge outside of the containerized system.

D) 1 set of high speed Decanter centrifuge. The 2-phase decanter centrifuge is outside of the containerized system to remove the fine solids.

E) Screw conveyor outside of the container. It is used to collect the cuttings discharged from vertical cuttings dryer and transfer to the cuttings box

F) Other accessory device for working tools, hand wash, etc…

- Details

-

Published: 27 November 2017