GN Solids Control is the No. 1 brand in China for direct importing of compact mud recycling system for different applications, like HDD, water well drilling, piling, micro tunneling, or other no-dig underground constructions.

Why GN Solids Control mud recycling system is hot sold and welcomed by international customers? Below are some of the reasons:

1) GN mud system capacity and shale shaker capacity is defined in real drilling mud condition, like the system capacity max. 120m3/h or 240m3/h, it means the shale shaker on the mud recycling system can handle max. 120m3 or 240m3 drilling mud with API 40 screen (400microns) for 1.2g/cm2 mud density and 40s mud viscosity.

There are many other brand, they write down a huge system handling capacity, but their handling capacity is under big opening steel screen for max. water flow. It has no meaning for clients to know the real mud capacity.

2) GN Solids Control utilizes high G force oil field shale shaker to treat drilling mud. The G force is up to7.5G, and it is adjustable. Furthermore, GN Solids Control offers high quality composite material or PU material replacement screens to suit for different mud condition. The composite material screen and PU material screen can last a much longer time than the traditional metal frame or steel screens. For other brand recycling system, maybe their shaker area is bigger, but their G force is small. It is only 4G or 5G. For the same screen area, its handle capacity is much smaller than GN Solids Control high G force shale shaker. So GN Solids Control shale shaker can handle a bigger mud flow with a smaller shaker screen area. It is more compact in design.

3) For the similar configuration, GN Solids Control price should be very competetive. GN Solids Control are the original mud system manufacturer. All equipment inside the system are made by GN. There are many companies, especially the rig companies, they do not make separation equipment, they buy equipment from others, and they only build the tank.

4) Per our understanding on some U.S mud system brands, their system price is not higher, but their system is too much simple. They care too much on compact design and ignore the performance. But GN Solids Control ensures the performance first, based on the performance; GN Solids Control tries to make it more compact. That is why many customers choose us after compare with U.S and German brand.

- Details

-

Published: 04 September 2017

After 2-months hard working, finally, GN Solids Control dispatched the full set helicopter lifting mud tank system. The total system including 11 modular as below:

1) There are 9 ea full functional mud tanks, complete with pipelines, walkways, ladders, guards, vales, electrical control systems, sun & rain sheds, and other necessary accessories.

2) 2 ea transportation frame for equipment and spare parts lifting and shipment.

It is a very special and difficult project. Every design, no matter how small, showed be caculated carefully, every spare parts and accessories should be chose from famous brand. Every design is new made, while the leading time is very very tight. Normally, for this kind of project, it should take a couple of months only to make sure the design drawings, not consider the manufacturing. But as the end user have strict time schedule, it cannot be changed. In order to support client for the project, GN people works for 7 and 24 hours, and finally finished the while system within a short time.

Why we say this oil rig mud system is very special and difficult? Below is some features of the system:

1) As the whole system is designed for helicopter lifting standard, the total weight of every single modular should be not more than 9 tons, but it is on condition that the storage volume and strength should be strictly ensured.

2) Furthermore, as the reason of safety and to comply with the HSE standard, every modular must be strong enough for helicopter lifting. And the lifting point should be specially design to suit for helicopter lifting. It must be strong enough and should be keep balance during lifting. Every design should come from strict calculated.

3) Every components of this mud tank system are chose from high quality and famous brand, like valves, unions, bearings, lights, motors, paint, etc…

4) All pipelines are made from SS316L for longer lifetime.

5) All welding jobs of this system should be complied with ASME standard, and should be tested by NDT.

6) Coating & Painting are chose from worldwide famous brand PPG

This projects give GN much experience on helicopter lifting system design and manufacturing. GN can offer more professional and fast supporting for any new helicopter lifting project in the future. Welcome customers contact GN Solids Control for any inquires.

- Details

-

Published: 11 August 2017

500GPM is a most popular size mud recycling system for HDD and water well drilling rigs. Recently, GN Solids Control dispatched a full 500 GPM mud recycling system for a VIP customer. This is the 4th mud system for this customer. They will use the system to match their Horizontal directional drilling rigs (normally called HDD rigs) for construction field.

The system is combined with below equipment:

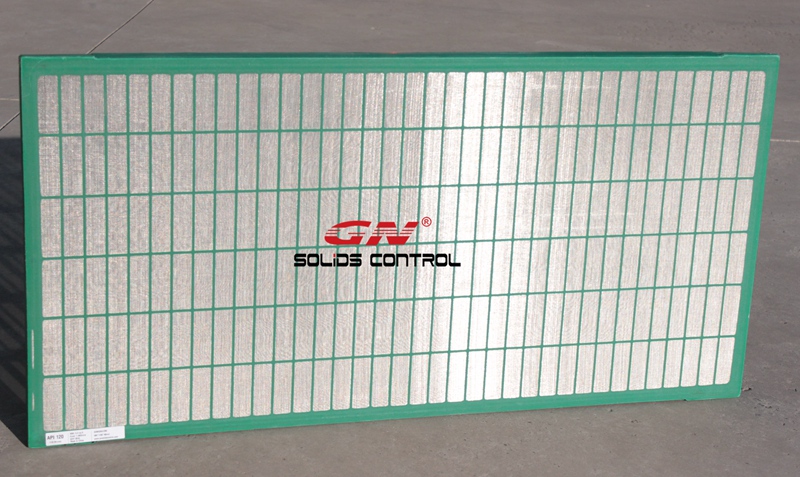

1) 1 set linear motion shale shaker GNZS594E-HB with 528GPM capacity. It is a 4-panel shale shaker with GN special design composite material screens. The composite material screen lifetime is nearly more than double compared with the old type metal frame screens. But GN composite material screen price is just a little bit higher than the old technology metal frame screens.

2) 1 set mud cleaner combined with a underflow shale shaker, 10 inch desander cones and 4 inch desilter cones. It contains 2 stages separation. The mud cleaner can remove solids above 27microns.

3) 2 sets centrifugal pumps are used to feed for the desander and desilter. The centrifugal pump is GN upgraded design. The impeller and pump casing is made from wear-resistance material for longer lifetime and to suit for hard materials. Furthermore, the centrifugal pump design is interchangeable with Mission Magnum pump. Even all the spare parts are interchangeable with Mission Magnum pump. So many customer can order GN centrifugal pump to replace their old Mission pump and order spare parts from GN.

4) 1 set of mud tank complete with pipelines, walkways, guardrails, ladders, electrical control system, lighting system, etc… The mud tank is with the same dimension of a standard 20ft container. All clean gate, values, etc… are insert type in avoid oversize. It can avoid to destroy any tank wall accessories during shipment. And customer can use standard container track for shipment.

5) A 20ft containerized skid for fast movement and easy lifting. The skid is used to mount shale shaker and mud cleaner. All pipelines are connected by fast connectors for east install and remove.

- Details

-

Published: 04 August 2017

As a leading brand GN Solids Control will come for SPE Offshore Europe this year. The time of the show is 5th ~ 8th Sept. It is the first time GN Solids Control comes for SPE Offshore Europe. But GN Solids Control already has a good sales record for UK and for Europe.

GN Solids Control will take the high quality replacement screens for SPE Offshore Europe exhibition. GN Solids Control makes high quality replacement composite material shaker screen for most of the popular shaker models, like for Derrick shakers, Swaco shakers and Brandt shakers.

SPE Offshore Europe is the leading exhibition for Engineering and petroleum on oil & gas field. Around 50000 visitors and over 1000 exhibitors from +150 countries will come for the show. The SPE Offshore Europe will be hold at AECC (Aberdeen Exhibition & Conference Centre), Exhibition Avenue, Bridge of Don, Aberdeen, AB23 8BL. It is a good chance for the petroleum field suppliers to meet with his potential customers, to communicate with their peers. And it is also a good chance for the suppliers to know the new trend and development of this field.

Besides the SPE Offshore Europe exhibition in UK, GN Solids Control will come for all the international big oil and gas field exhibitions, and many professional exhibitions in certain regions. Below is the exhibitions GN Solids Control will come and already came for:

1) CIPPE oil show in Beijing in March, It is second largest oil show in the world.

2) OTC oil show in March in Houston. GN Solids Control and GN Solids America comes for OTC oil show for over 5 years. GN Solids America is the 1rst Chinese solids control brand open brand company in USA.

3) MIOGE exhibition in Moscow in June. It is the largest exhibition for Russian countries.

4) ADIPEC in Nov. in Abu Dhabi. UAE is a center city for petroleum field. Most international huge oil company, drilling company, petroleum company and services companies, they will open offices in UAE. Visitors and exhibitors comes from Middle East, Africa, East Asia and Europe comes for the big event.

- Details

-

Published: 28 July 2017

Weeks ago, GN Romania partner accompanied the end user, a drilling rig contractor in Romania, came to GN Solids Control main factory in Beijing China, to check their full set mud solids control system for their new rig. It is full set mud solids control system for their 1000hp oil rig. The system is made per CE standard for European market. The electrical system is also made per European standard ATEX.

They checked the quality and the performance of the mud solids control system, and very happy with GN products. After their check, GN Solids Control logistics team dispatched the system to the Tianjin seaport for international ocean shipment.

It is a full set mud solids control system with 3 stages solids control process and 4-stage treatment.

The first step solids control process is 3 sets linear motion shale shaker, GNZS594E. It is GN latest design 4-panel shale shaker. And it is one of the most hotel sale equipment model from GN. The shaker deck is made from stainless for longer lifetime. Vibration motor is choose from Italy Oli (US Martin is available if client request).

The second step and the third step is by mud cleaner, it is combination of linear motion shale shaker, desander and desilter. The underflow shale shaker is the same with the 1rst step solids control shale shaker for spare parts interchangeable.

Furthermore, the 1000hp oil rig mud solids control equipment is equipped with below equipment:

1) 1 set of vacuum degasser. GN special design vacuum degasser is self-suction type.

2) 2 sets of centrifugal pump feeding for the desander and the desilter. The pumps are interchangeable with NOV Mission pump.

3) Dual hopper and dual pump mud mixing system, to mixing new chemicals for the system

4) 20 sets mud agitator for shale shaker tank, suction tank, mixing tank and storage tanks.

5) Mud tanks for the full mud solids control system, including trip tank, shale shaker tank, suction tank,

- Details

-

Published: 22 July 2017

GN Solids Control is a leading manufacturer and a famous international brand of waste management solution, like oily sludge separation system, contaminated soil clarification system, waste oil recovery system, waste water recovery system and other liquid and solids separation plant. GN Solids Control has branches in many major markets, like GN Solids America in Houston America, GN Solids Russia in Moscow

Weeks ago, GN Solids Engineers came back from a Middle East oily sludge separation jobsite. They finished the job there for a commissioning of a separation plant to treat oily sludge and the contaminated soils from oil and gas drilling activities.

The end user let a U.S consultant company to choose the right suppliers for their projects. Other compare various brand, they compare their solutions and their experience on similar jobs, finally, the U.S consultant company choose GN Solids Control.

Based on the oily sludge condition, and the client requirement, GN Solids Control offer them a customized solution. Before the system sent to clients jobsite, the US consultant company sent engineer to GN Solids Control to check the system. They are happy with the system and approve the ship to the jobsite.

It is a complete oily sludge separation system including following treatment modular:

1) The pre-mixing and heating module. It is a mixing tank and agitator and transfer pump, and equipped with heating system.

2) Solids Control separation modular: it is including mud tank, high G drying shaker and decanter centrifuge separation system.

3) Chemical dosing modular. It is a 20ft containerized chemical dosing system for automatically chemical dosing. The dosing system can be used for 2 kinds of chemical dosing.

4) 3-phase separation modular. The modular includes an included plate clarifier, an oil water separator, oil transfer pump, water transfer pump, oil surge tank, water surge tank, and an oil field skid for all above.

After the oily sludge separation system arrive jobsite, GN Solids Control sent engineers to jobsite for 1 month to help for the commissioning and to training their people.

- Details

-

Published: 14 July 2017