Chinese New Year is also named the Spring Festival. We can say it is one of the biggest celebrations in the world. Nearly 1/6 of population in the world will joint in the big events. It is not only a holiday, it is the large population migration.

The migration population during the Chinese New Year is around 3 billion. People try every try for going home: by air by train, by bus, by self-driving, etc… Express train as its fast speed, reliability and convenience, attract most people. Beijing airport and Beijing west railway station as the biggest access in China. Take Beijing West railway station for example, their single day throughput of passengers is equal to half of London population.

Chinese New Year means the first of Lunar Calendar, the celebration will last 15 days, from the 1rst day of Lunar year until the 15th day of Lunar year. It is no-doubt the biggest celebration in China, and absolutely the most important event for all Chinese people and overseas Chinese. During the New Year, people will go home from every corner of China, and from worldwide, no matter where people are working, no matter how far, people have the same aim: Go home, especially go back to the hometown.

For many young people from the countries, even they buy a house in the city, their parents comes to the city to live together with them, still they prepare to go back to their hometowns, to celebration with their old friends and relatives.

As many of GN workers are from other city and province of China, they have few chances to go home.

GN Solids Control will take a New Year celebration party at night of 21rst Jan., to thank the hardworking of all GN people through the year. After the celebration party, people will leave for home, to enjoy a 2-week holiday. People can enjoy nice food, wonderful shows, dancing shows, magics, etc... The most exciting time is for price draw. Furthermore, many special gifts will be given during the New Year celebration party.

- Details

-

Published: 24 January 2017

GN Solids America belongs to GN Solids Control. GN Solids America has its own warehouse and office building in Windfern Road, Houston, TX. For a fast support to surrounding market, GN Solids America always keep stocks for most of the popular solids control equipment, drilling waste management equipment, and high quality replacement screen for different shaker models. GN Solids America also offers rental services.

What equipment stock you can get from GN Solids America:

1) Solids Control equipment: like linear motion shale shaker, dual motion shale shaker, jet mud mixer, mixing hopper, mini size centrifuge, barite recovery decanter centrifuge

2) Drilling waste management equipment: Vertical cuttings dryer, high G drying shaker, high speed decanter centrifuge, variable speed decanter centrifuge, screw conveyer, screw pump, centrifuge operation skid, VG dryer operation skid

3) Different brand replacement shaker screen, especially the high quality composite material replacement screen for Swaco shale shaker and mud cleaner, Brandt shale shaker and mud cleaner, Fluids system shale shaker and mud cleaner, Derrick different models shale shaker and mud cleaner.

4) Other wearing spare parts for GN brand equipment, for shale shaker, mud cleaner, centrifuge, pumps, agitators, etc.. And some general spare parts.

GN Solids America is one of the separate brand from GN Solids Control. GN Solids Control set his headquarter and main factories in Beijing China. GN owns 2 new fabricated factories in Beijing. The 2 factories are equipped with the most advanced designed processing machines from worldwide. GN Solids Control is among the few companies who have the capability of super high speed and big bowl decanter centrifuge design and manufacturing.

Up to now, GN Solids Control owns 4 brands for different market:

1) GN Solids Control: It is the main brand, based in China for international market.

2) GN Solids America: It is based in Houston America, mainly for South and North America, and other international market.

3) GN Solids Australia: It is mainly for Australia and New Zealand.

4) GN Solids Russia: It is for Russia speaking countries.

- Details

-

Published: 21 January 2017

Recently, a batch of solids control equipment dispatched the port for a Russia client. The order includes solids control shale shaker, decanter centrifuge and centrifugal type degasser. They will service 10 oil drilling rigs in Russia. Before they give the order to GN, they visited many Chinese suppliers. But finally, they decided to buy from GN.

Why they decided to buy from GN after they compare so many suppliers? Below are some of the reasons.

Firstly, GN is the China leading brand for solids control and drilling waste management. GN offer turnkey solution for various kind of drilling mud treatment solution, like oil and gas drilling rig, HDD drilling rigs, CBM drilling rigs, Geothermal drilling rigs, piling, micro tunneling, mining, etc…

Secondly GN is the first API certified solids control manufacturer in China. And GN is the first Chinese solids control manufacturer who opened a separate brand GN Solids America in Houston USA.

Thirdly, GN mainly focuses on China top market and the international market. All materials used are chosen from famous brand or worldwide famous brand. Clients can see it when they visit GN factory in Beijing and feel GN quality.

GN owns rich experience on international big project operation. GN knows well what client want. And they know how to meet the clients request.

The client is on top urgent to use the mud solids control equipment for their rigs, GN Solids Control can ensure a very short delivery with reliable quality. When the client visit GN factory, they can see GN has stock for most of the main equipment: shale shaker, mud cleaner, desander, desilter, hopper, mixer, different size decanter centrifuge, and even the complete mud cleaning system for pipling and micro tunneling. As many of GN regular clients clients request for stock. Once they get the project, time will be very tighter for them to get the facilities. GN invests more to support them with reliable stock quantity.

Furthermore, the client know GN did many project in Russia, most of them are big companies, they are very happy of GN equipment and delighted to recommend GN brand.

- Details

-

Published: 13 January 2017

What is the function of drilling waste cuttings?

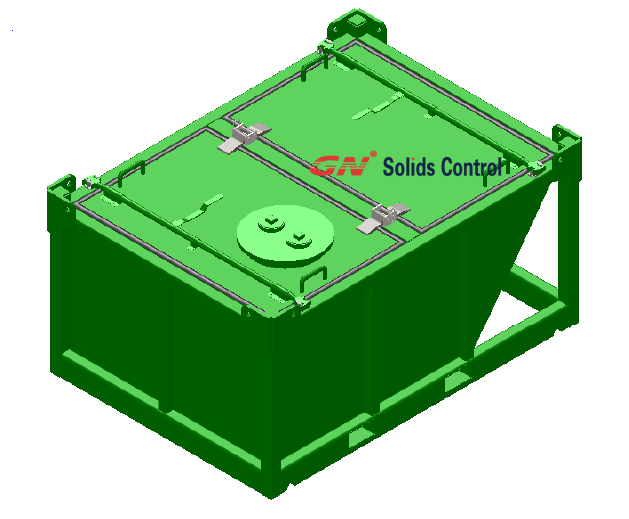

Drilling waste cuttings container is also called drilling waste cuttings bins, mud cuttings skips. GN specially designed drilling mud cuttings skips are used for transportation and safe handling of hydrocarbon contaminated drill cuttings. It is can be used for offshore to and from offshore platforms. The drilling waste cuttings containers provide a safe and efficient means of containment of drilling waste for transport to treatment and disposal sites.

GNYXH-030 drilling mud and cuttings container meets DNV lifting regulations for offshore applications. The GNYXH-030 drilling waste mud and cuttings container is completed sealed to avoid spill during transportation. And the cover is designed with an easy lock and unlocks system for fast opening and closing. It is the ideal container to meet the HSE regulations for hazardous waste movement.

It can stock and move drilling mud cuttings from one place to another place, or collect the waste cuttings to different equipment or system for treatment, like high G drying shaker, high speed centrifuge, vertical cuttings dryer, solidification unit or TDU.

GN brand drilling mud and cuttings container can meet below features:

1) GN brand drilling mud and cuttings containers are designed and manufactured per DNV 2.7-1/ EN12079 standards.

2) Certified Slings complete with shackles are provided according to DNV 2.7-1/EN1207 standards

3) GN brand drilling mud and cuttings containers are completed sealed to avoid spill during transportation

4) Specially designed cover with Light weight, it is easy and convenient for operators to open and close it.

5) The cuttings container top cover be can opened fully. Maximum the ability to fill waste cuttings. Improve the efficiency of hazardous waste logistics.

6) The drilling cuttings containers can be stacked together to save shipping space and easy for stock.

7) Rigid construction for long life time.

8) The drilling mud and cuttings containers are with sloped tank bottom for easy and fully discharge.

- Details

-

Published: 25 December 2016

2 sets 14 inch high quality decanter centrifuge was dispatch to the sea port from GN Solids Control Beijing factory this week. After 1 month sailing on the ocean, they will arrive South America to client's jobsite. The client will use it in his mud solids control system.

It is a 14 inch popular size 2-phase decanter centrifuge. The centrifuge is widely used for mud solids control and drilling waste management. It is also a very good choice for oily sludge processing projects.

Firstly, 14 inch centrifuge can be used in drilling fluids mud recycling system, to recovery the barite for reuse. In the case of the mud is weighted and it is not suitable for drilling activities, the 14 inch decanter centrifuge can be used to remove the fine solids, and enable the drilling fluids qualified for the mud system.

Secondly, the decanter centrifuge can be used after high G drying shaker and vertical cuttings dryer to treat the drilling cuttings from solids control system.

The cuttings from solids control system, especially from shale shaker, desander, desilter, mud cleaner, contains high quality usable drilling fluids. From one side, the usable drilling fluids are valuable. It is better to recovery as more as possible to save cost. From another side, the high percentage drilling fluids makes the liquid percentage is too much high, it is not convenient for movement, and also the oil content is too much higher, it is hazardous to the environment. It cannot be discharged. Decanter centrifuge is one of the essential equipment used to retreat the drilling cuttings.

Another popular application of decanter centrifuge is for oily sludge separation. There is a variable source of oily sludge: from refinery, from drilling, from tank cleaning, etc…The oily sludge with various percentage of solids and water. Decanter centrifuge will be used together with chemical dosing system to process the fine soil in the oily sludge.

- Details

-

Published: 17 December 2016

GN Solids Control is a professional manufacturer on waste management on drilling field.

GN Solids Control offers complete solution of 3 phase separation: soil, water and oil separation. GN Solids Control can treat various types of oily waste, especially from drilling field and refinery companies.

What kind of waste GN Solids Control can treat? Below are some of the items, but not limited to the below items:

1) GN Solids Control can offer solution to the waste pit generated from drilling activities. There are huge quantities of waste. It is mixture of heavy oil, diesel oil, drilling cuttings, disposed drilling fluids, rain water, etc…

2) GN Solids Control can offer solution to the sludge waste from refinery. The waste normally contents sand, soil, crude oil, water and other kinds of waste oils. GN Solids Control can separate the solids phase, and get oil and water. The oil can be used to get oil products, and water can be reused for industry.

3) GN Solids Control can offer solutions of waste water and slurry generated from underground constructions, like piling, micro tunneling, HDD, etc… In more and more countries, the government as higher standard on industry and construction field waste water discharge. They cannot discharge the slurry directly. If they let the professional waste water treatment company to do the job, they charge per ton, it is high cost for the long run.

What equipment GN specially designed for waste management? Below are some of GN design waste management equipment:

1) High speed centrifuge and Big bowl centrifuge, Full hydraulic drive centrifuge

2) Vertical cuttings dryer

3) Drill cuttings solidification unit

4) Chemical dosing system

5) Thermal desorption unit

6) Vacuum pump

7) Oil/ water separator

8) Automatic tank cleaning system (ATC)

GN Solids Control offers customized solution to suit clients special request. If you have any question, welcome you contact GN international service center for support.

- Details

-

Published: 04 December 2016