GN Solids Control is a leading solids control manufacturer from China. GN Solids control main market is for international clients. As GN do not have special relationship with China government, CNPC companies, or SINOPEC companies, it is difficult for GN to sell to the major drilling companies and services companies. GN Solids Control can only make high quality products with competitive price, and offer reliable services for international customers.

It is good that after years of hard working and fast development, GN Solids Control becomes a leading brand for mud solids control and waste management equipment. And also GN Solids Control becomes an international famous brand. Now GN Solids Control has 3 international branches: GN Solids America in Houston, GN Solids Control Russian, and GN Solids Control Australia. GN Solids Control set up international warehouse and service center to offer fast and on time services to worldwide clients.

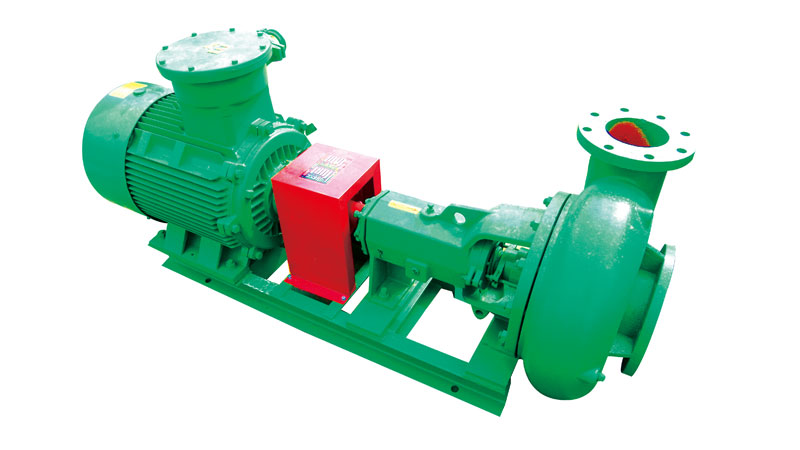

High quality interchangeable centrifugal pump and pump spare parts are a main business of GN Solids Control company. As we all knows, Mission type pump is a most popular centrifugal pump design for oil and gas drilling field. Many clients own Mission pump. Centrifugal pump requests many high consumable parts. And even the centrifugal pump itself cannot last for long time. Per different job site condition, the total Mission centrifugal pump should be changes. GN Solids Control B generation centrifugal pump is completely interchangeable with NOV Mission pump, no matter the pump design or the footprint. It means clients can use GN brand centrifugal pump to replacement the old Mission pump, and they do not need to make any changes.

All GN Solids Control centrifugal pump is mechanical seal for reliable performance and longer lifetime. Below is the main centrifugal pump model offered by GN Solids Control:

GNSB8x6B-14J, GNSB8x6B-12J, GNSB8x6B-13J, GNSB8X6B-11J, GNSB6x5B-13J, GNSB6x5B-10J, GNSB6x5B-12J, GNSB6x5B-9.5J, GNSB5x4B-13J, GNSB5x4B-11J, GNSB5x4B-12J, GNSB5x4B-10J, GNSB4x3B-13J, GNSB4x3B-12J, GNSB4x3B-12J, GNSB4x3B-10J, GNSB4x3B-11J, GNSB4x3B-9.5J

Furthermore, GN Solids Control can offer all the spare parts for NOV mission pump, including mechanical seal, pump casing, oil seals, bearings, couplers, housings, impellers, etc…

- Details

-

Published: 04 June 2017

After over 10 years fast development, GN Solids Control becomes a leading branding from China. With is top ranking quality and reliable services, GN Solids Control owns a very good reputation for its brand. GN Solids Control now is mainly competition with U.S Derrick, Swaco and Brandt. GN Solids Control always focus on the Top quality products. 70% of GN Solids Control sales are from international market.

In the early of 2017, an European client give an order to GN for 3 sets complete solids control equipment for their oil rigs. It is the first time they buy Solids Control equipment from China manufacturer. They are very careful. Before making decision to buy from GN, they send engineering team visited nearly most the solids control manufacturer in China. After comparing different peers, the European clients are impressed by the manufacturing and designing capacity of GN Solids Control. They ensure, GN is the best choice.

GN Solids Control is located in China, the main parts are made in China, but all GN mateiral are choose from top brand and top ranking. GN products quality and design is very international. It is impressive.

As the huge quantity, GN dispatched the 3 sets oil rig solids control equipment to end user in 3 batches. And all the 3 sets oil rigs solids control equipment are finished within 45 days. It is a very impressive short time for such big order. The client is very happy about the short delivery time.

The order for 3 oil rigs including below solids control equipment:

1) 9 sets solids control shale shaker. It is 4-panel linear motion shale shaker with 500GPM capacity. Screen is interchangeable with Swaco Mongoose shaker. GN also offers high quality composite material replacement screen for different shaker models.

2) 3 sets solids control mud cleaner. It is a 3-1 equipment with the function of shale shaker, desander and desilter.

3) 6 sets solids control decanter centrifuge for barite recovery and for fine solids separation.

4) And other accessory equipment to match for the above solids control equipment.

- Details

-

Published: 13 May 2017

Centrifuge dewatering package is widely used for municipal waste water treatment and reuse plant.

GNDU2000 Series 20 Feet Containerized Dewatering Unit dewatering package is a classic automatic polymer preparation unit. The dewatering package is including below items:

1) 1 set Three Tank Automatic Powder Polymer Mixing System for non-stop polymer mixing. The 3-tank PAM mixing tank is made from stainless steel. It is equipped with a stainless steel mixing hopper and 2 ea stainless steel mud agitator.

2) 2 sets Powder Polymer Dosing Pump, one for chemical dosing, and another one as back up.

3) Frame and skid for chemical dosing pump and back up pump, pipelines, pressure gauge and valves.

4) 1 set of Coagulant Mixing Tank equipped with mixing agitator and level meter.

5) 2 sets of Coagulant Dosing Pump. One for chemical dosing, another pump is for back up. The dosing pump is equipped with PLC and VFD control system for adjustable chemical dosing.

6) Other components, like the modified 20 ft container with lighting systems, stairs, the electrical control systems.

Why we call the system as continue PAM mixing and dosing system?

Mostly, the polymer will need some time to become ripening. There are 3 tanks in the chemical dosing system, the first tank is equipped with mixing hopper, it is for polymer mixing, after mixed well, the chemical liquid flow to the 2nd tank for preparation. Then the qualified chemical liquid flows to the 3rd tank. The 2nd and the 3rd tank is alternatively. When the 3rd tank chemicals are run out, then it is used as a ripening tank, and the 2nd tank with ripen chemical can be dosed to dewatering unit. It is the non-stop continue chemical mixing and dosing system.

High speed decanter centrifuge is the most popular equipped to be used together with dewatering unit. The centrifuge dewatering unit can be used to remove the ultra fine soil in the liquid mixture.

- Details

-

Published: 13 May 2017

Oily sludge separation is one of the main business of GN Solids Control. GN solution is machinery separation plugs chemical. GN Solids Control can offer turnkey solution per clients’ request.

GN Solids Control has many oily waste recovery systems running in COSL. Client can check the jobsite video in GN Solids Control website

http://www.gnsolidscontrol.com/video/oil-sludge-waste-treated-by-gn-centrifuge-with-chemical-for-cosl

Just 2 weeks ago, a full set contaminated soil treatment system was dispatched to a U.S clients. The system is used to remove the oil from the contaminated oil. To get clean soil, clean oil and recyclable water for industry.

http://www.gnsolidscontrol.com/drilling-fluids/a-bunch-of-soil-remediation-equipment-for-us-client

Main equipment of GN Solids Control oily sludge treatment modular unit is as below:

Modular unit -1): Pre-mixing and heating tank. The tank is used to dilution, and heating the oily sludge. Chemical will be used to reduce the density and viscosity of the oily waste.

Modular unit -2) Shake shaker separation tank. The content of the oily pit is very complex. Shale shaker will be used to remove the big size solids or rubbish waste, like bolts, nuts, sheet, rocks, gloves, etc…

Modular unit -3) High speed centrifuge will be used together with chemicals to remove the fine solids. GN offers different size decanter centrifuge to suit for different treating capacity, it varies from 14inch to 22inch.

Modular unit -4) 3 phase separation system. The system included a inclined plate clarifier, gravity oil water separator, surge oil tank, surge water tank, oil transfer pump and water transfer pump.

Below are some questions to help you get a suitable oily sludge separation system. But is not only limited to these questions:

1) What is the treating capacity you want to treat the oil sludge?

2) Where is the oily sludge come from, from drilling, from refinery, from tank cleaning, or from other source?

3) What is the final condition you want to get about the final products oil, water and soil?

For any questions or inquire about the oily sludge treatment, welcome you contact GN Solids Control freely.

- Details

-

Published: 28 April 2017

2 full sets cutting drying system will be finished soon and will be dispatched to South America. The drying system can be used to treat both oil base mud cuttings, as well as water based mud cuttings.

The cuttings drying system for South America client is customized per client’s request. The client purchases from GN for many years. They owns many of GN equipment, especially decanter centrifuges, they have over 10 sets different models of GN decanter centrifuge, for both drilling rig solids control system and drilling waste cuttings treatment system. As the client said, all GN equipment works well so far. That is why they continue order new systems from GN. This time, the client ordered the 1-skid cuttings drying systems. They want the systems to help them expend their business.

The system is including following equipment:

1) GNCD930D vertical cuttings dryer. The GN Vertical Cutting Dryer uses centrifugal force to dry drilled solids in oil or synthetic base fluids. A stainless steel screen bowl traps “wet†solids and accelerates them up 900RPM with G force to 420G or super high speed 1200RPM with G force to 750G The can reduce oil on cuttings to 3% or 5%. 3% ~ 5% oil on cuttings is the discharge requirement in most countries.

2) Linear motion High G Force Drying shaker GNZS594HGE-LD.

GN high G shaker is designed for primary solids control separation, as well as drying the cuttings from the primary solids control equipments, recover silts and ultra-fine sands, provide solids in a consistently stackable and conveyable form and requires no expensive chemicals or polymers. GN high G drying Shaker with Adjustable G force Up to 8.0 G.

3) High speed decanter centrifuge GNLW336CG-VFD. The high speed centrifuge is used to remove ultra fine solids from the recovered liquid from high G shaker or decanter centrifuges.

1-skid cuttings drying system is equipped with both VG dryer and high G dryer, jobsite operators can choose the suitable separation equipment per his jobsite condition.

- Details

-

Published: 21 April 2017

A full set of contaminated soil washing cleaning system will be finished this week and dispatched to the port soon. The whole system is ordered by an America customer. This is one of the orders they give to GN Solids Control.

The clients just visited our factory to check and system performance. They are happy with the system test performance and are happy with GN professional manufacturing capability and quality control ability. GN Solids Control help the client arranged shipment per client’s instruction. The contaminated soil washing cleaning systems are disassembly for sea worthy packing, and will be dispatched to the port tomorrow.

Before the client gave order for the complete contaminated soil washing cleaning system, they preferred to only order the major equipment and pumps, they build the tank and electrical control system locally. But finally, they are compressed with GN turn-key solution, and gave order for the complete contaminated soil washing cleaning system.

The complete contaminated soil washing cleaning system is designed to suit for 55C degree high temperature area. And it is applied with explosion for hazardous areas. The soil remediation system is including below function and equipment:

1) Pre-heating system: It is a 1-tank mixing tank with heating system. Mud agitator and slurry pump is equipped on the tank.

2) High G drying shale shaker separation system: It is used to remove the big size solids. The shaker is mounted on the pre-mixing tank for a compact design.

3) Big bowl decanter centrifuge GNLW553C-VFD unit: The centrifuge unit is complete with feeding pump, working skid, and smart control VFD control panels.

4) 3-phase separation system: This unit is used to separate oil, water and the fine solids in the recovered liquid.

5) 20FT containerized chemical dosing system.

If you are interested in any equipment or need more information, welcome you contact GN Solids Control any time.

- Details

-

Published: 09 April 2017