GN dispatched over 30 sets high speed and low speed decanter centrifuges for an Algeria projects in the beginning of year 2015. Till now the centrifuges are running nearly 1 year. The clients are happy with the performance and highly commended with GN centrifuge performance and GN people services.

All the centrifuges are the model GNLW363CG. GN C class decanter centrifuges is the 3rd generation. It is the latest design from GN Solids Control company. All the centrifuges are equipped at jobsite for mud solids control and drilling waste management. They are used to recovery barite from drilling fluids in solids control system. And in the waste management system, they are running in high speed to separate the fine solids and reduce the weight of the mud.

Based on the latest and advanced design of GN Solids Control decanter centrifuge, the centrifuges for Algeria project are capable with below features after some value-additional design.

1) All the centrifuges are fixed speed control. But the operators can change speed through changing pulley and belt. All the centrifuges have 4 speeds for optional: 3200rpm, 2800rpm, 1800rpm, 1600 rpm.

2) There are temperature senses for the main bearings at both ends. Then bearing temperature can display on the electrical control screen. The operators can set up the max. temperature allowed for the centrifuge bearings, then when it is over heat, the centrifuge will shut down to protect the machine.

3) The explosion proof control panel are made from high quality aluminum. The lifetime is long. And it is with a better performance for sealing. And also the appearance is nice.

4) The screw protection for the centrifuge is interchangeable tungsten carbon tile. It is much more reliable than the normal way hard surface welding.

Besides above point, the GNLW363CG new design decanter centrifuges are with below features:

1) It is more user friendly.

2) The performance is more reliable.

3) It is more east for operation and maintenance.

4) The lifetime is longer as it is made from upgrade material.

- Details

-

Published: 19 February 2016

As worldwide famous manufacturer on oil field mud solids control equipment and drilling cuttings waste management equipment. GN Solids Control advanced design decanter centrifuges earned a good name worldwide. All control system for the centrifuges are design and made by GN own engineering team.

Positive pressurized control panel for variable speed frequency control are mostly equipped for GN high quality waste decanter centrifuge and vertical cuttings dryer. The explosion proof enclosure is made from anti abrasive stainless. Inside components of GN Positive pressurized control panel are all chosen from international famous brand: Schneider, Siemens, ABB, etc…

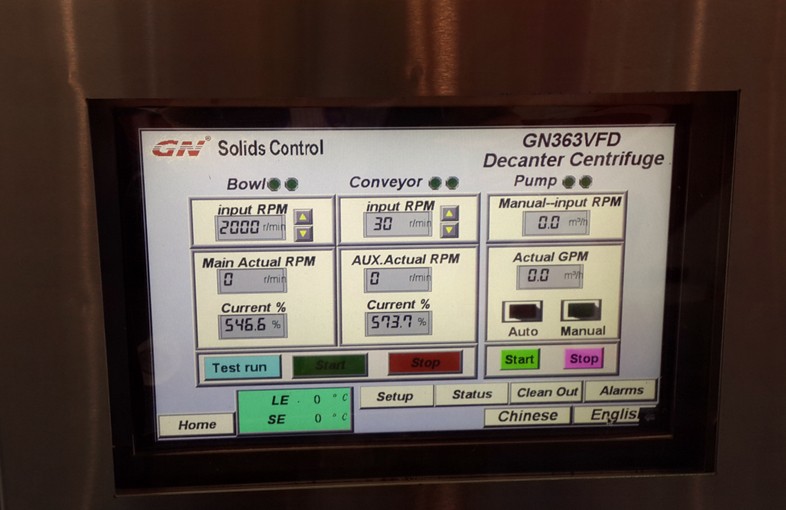

Positive pressurized control panel is a light point of GN. It is not only for start and stop of the equipment. But also, GN giant engineering team developed his own programmer with PLC for smart control. The PLC control panel for VFD centrifuge is not only control the main motor and back motor of the centrifuge; it does also control the pump and offer a variable speed.

As most GN equipment need to equip electrical control panel, and all clients eagerly request high quality explosion proof control system with processional design, good price and short delivery time. GN Solids Control developed his electrical control department and make high quality explosion proof control panel, complete electrical control system and junction box only only for GN equipment, but also for different applications. GN Solids Control is certified manufacturer of explosion proof control systems.

Flame proof is the most common type for explosion proof control panels. It can be applied for mud agitator, centrifugal pump, shale shaker, mud cleaner, mixing unit, oil and gas drilling mud solids control system, HDD / CBM mud recycling system, no dig desanding plant, fixed speed or variable speed for screw conveyer, and other applications.

The enclosure of GN flame proof type Explosion proof control panels are made out from high quality abrasive resistant Aluminum. It is with nice appearance, better sealing performance and light weight. It suits China National Explosion Proof (CNEx) standard. The protection level of GN standard Ex control panel is IP56, and suits for Class 1 Division 1, group C and D.

If you have any questions regarding explosion proof control panel or system, welcome you contact GN Solids Control freely.

- Details

-

Published: 09 February 2016

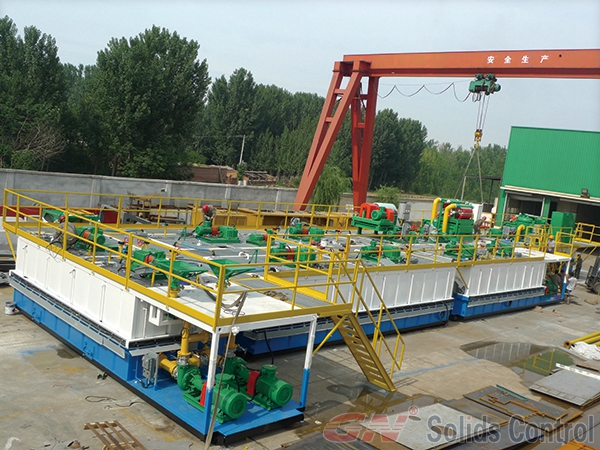

In nowadays, a complete oil and gas drilling rig should be equipped at least 2 mud systems: One called solids control system for drilling fluids treatment; another system called the pitless mud system for drill cuttings treatment.

Many clients are wondering, if the pitless mud system for drill cuttings system can replace the shaker tank system or not?

Firstly, we have a draft idea about the 2 mud systems.

Solids Control system for drilling fluids treatment

Complete solids control system can be composed of 4-stage solids control equipment or 5 stage solids control separation process.

The 1rst stage solids control equipment: shale shaker. It is used to remove the coarse particles from the drilling fluids.

The 2nd stage solids control equipment: Desander, it utilizes 10’’ hydrocyclone cones to remove particles above 47 microns.

The 3rd stage solids control equipment: Desilter, it utilizes 4’’ hydrocyclone cones to remove particles above 27 microns.

The 4th stage solids separation equipment: Decanter centrifuge. It utilizes centrifugal force to remove the fine solids to 2 ~ 5 micron. Middle speed decanter centrifuge is normally used this stage to recovery the barite.

The 4 stages solids control equipment composed of 4 stage separation. Another separation is for vacuum degasser. It is used after shale shaker and before desander desilter.

Clients chose the suitable separation machine per rig condition.

As the mud pit is forbidden in China at the rig site, pitless mud system for drill cuttings treatment are more and more equiped.

1) High G drying shaker, it is normally used to treat water base drill cuttings.

2) Vertical cuttings dryer. It is used to treat oil base drill cuttings.

3) High speed decanter centrifuge will be used after high G drying shaker or vertical cuttings dryer to separate the fine solids

4) Dewatering unit. If there are many ultra fine solids cannot be removed by centrifuge directly. Dewatering unit for chemical dosing will be used.

- Details

-

Published: 02 February 2016

GN Solids Control (with a separate US brand and company, GN Solids America) is a leading manufacturer for drilling waste treatment system. GN brand drilling waste management equipment and system are sold to over 60 countries and regions worldwide, including USA, Canada, Argentina, Brazil, Chill, Egypt, Algeria, Libya, Saudi Arabic, Iran, Iraq, Nigeria, Turkey, India, Indonesia, etc…

GN drilling waste treatment system are suitable to treat the drilling cuttings with rigs or in the waste mud pit.

Below is a general idea of the treatment for oily waste from drilling rigs or from oil refine industry.

Step 1: Oily sludge mixing tank, 1 ea

The oil waste from mud pit goes to the tank and it is mixed with chemicals. There is mud agitators equipped to the tank to stirring the oil waste with chemicals. The chemical is used to make the oil comes out from the waste. The oil, waste and solids are easy to layering after settle down. Solids from the tank goes to shaker for treatment.Liquid goes to oil water separator.

Step 2: High G drying shale shaker 1 ea and Decanter centrifuge 1 ea. This step is for mechanical separation.

A 4-panel high G drying shaker is used in this step. The shaker is used to remove coarse particles from the oil waste. The liquid will be further separated by the 1# decanter centrifuge. Solids phase from shale shaker goes to TDU for further dry. Liquid phase from 1# decanter centrifuge goes to dewatering unit and then separated by high speed centrifuge.

Step 3: Dewatering unit and a high speed Decanter centrifuge 2# for remove the fine solids

Flocculants from dewatering unit is mixed with the liquid from 1# decanter centrifuge. And then the mixture of chemical and liquid goes to centrifuge 2# for treatment. Solids from 2# decanter centrifuge goes to TDU. The Fluids from 2# centrifuge is mixture of oil, water and small content of ultra fine solids, they can go to oil water separator.

- Details

-

Published: 29 January 2016

Centrifuge is a core separating machine. It utilizes centrifugal force to separate the particles and liquid from suspensions, or separate two different density and immiscible liquids from emulsions. Decanter centrifuge is a kind of centrifugal machine. It is widely used in oil and gas drilling field, for food industry, for chemicals, for waste water treatment and oily sludge separation.

Below is a general proposal for water base drilling fluids treatment.

As decanter centrifuge cannot allow big size particles and cannot treat high solids content material. Firstly, shale shaker or mud cleaner, desilter should be used to remove the bigger particles and reduce the mud weight. From this step, most particles over than 30 micron will be removed.

Secondly step, a middle speed decanter centrifuge (GNLW363CG, GNLW363CG, or GNLW452) can be used to further reduce the solids content in the fluids. Decanter centrifuge for this step can be fixed speed, and use a middle speed to reduce the mud weight. From this step, most particles over than 5 ~ 6 microns can be removed.

As the separation point of high speed decanter centrifuge is 2 ~ 5 micron. There are high content ultra fine solids cannot be treated. In this case, the chemical dosing system (also called dewatering unit) will be used before high speed centrifuge. Flocculant will be used in this step to help the solids settle down and easy for treatment.

A high speed decanter centrifuge (GNLW363CG-VFD, GNLW453C-VFD, GNLW553C-VFD) will be used together with the dewatering unit. Chemicals and drilling fluids will be mixed before enter into centrifuge bowl. The dewatering unit decanter centrifuge should be variable frequency control. Operator can adjust to find out the most suitable speed and G force to optimize the performance. GN offers different bowl diameter centrifuge for option: 14’’, 18’’ and big bowl 22’’.

After above treatment, the solids phase is dry enough for truck shipment, GN do also offers drill cuttings solidification unit for treat the solids.

And the fluids phase can meet the industry discharge requirement in most countries.

- Details

-

Published: 22 January 2016

World leading manufacturer GN Solids Control offers complete drilling waste management system of water base mud and water base drilling cuttings, as well as oil base mud and oil base cuttings. Water base mud is the most normal type drilling mud for oil and gas drilling, especially in China. Here we have a brief introduction of the treatment system for water base mud and water base cuttings.

GN Solids Control system can recovery drilling mud as more as better, and reduce amount of solids waste as less as better. After the GN system treatment, the fluids can clean enough for reuse for discharge. The solids phase is harmless and dry; it can be used to make bricks or other applications.

GN no pit drilling waste management system for water base mud and water base cuttings are welcomed in China and outside of China. Like CNPC, CNOOC and SINOPEC are all equipped with GN brand drilling waste management.

The equipment for water base mud and water base cuttings are as following:

1) High G drying shaker. It is also called High G dryer, or drilling cuttings dryer. The Qty is 2 ea for 1 system. Model GNZS594HGE-LD. The shaker model is the 5 generation high G dryer shaker from GN Solids Control. GN own over 10 ea patent design for its main line equipment.

2) High speed decanter centrifuge GNLW363C-VFD. It is the most advanced design centrifuge for waste management from China. It replaced many U.S brand at different jobsite with its mature design and reliable performance.

3) Chemical dosing system and dewatering centrifuge: If the clean fluids from the high speed centrifuge will not be reused for drilling, it will be transferred to chemical dosing system (or called dewatering unit) for further treatment. After this step the fluids is clean and can be discharged.

4) Drill cuttings solidification unit. It is used to treat all the solids phase discharged from high G dryer shaker, from high speed decanter centrifuge and from the dewatering centrifuge. After the treatment of solidification unit, the solids can be used to make bricks for road construction.

- Details

-

Published: 15 January 2016