At GN Separation, we are dedicated to delivering high-quality separation equipment to meet the unique needs of our clients. Recently, we completed factory testing of two units of the GNGQ150 High-Speed Tubular Centrifuge (also known as Tubular Bowl Separators) before shipping them to an overseas client. These units are designed to provide efficient solid-liquid separation in industries such as pharmaceutical, food, chemical, and biological products, making them ideal for use with fermentation broths.

- Details

-

Published: 17 January 2025

In the Middle East, soil remediation projects require efficient and reliable technologies to handle high volumes of wastewater and sludge. To meet these demands, GN Separation offers an innovative solution: the GN Containerized Sludge Dewatering Package. This solution is designed to provide efficient dewatering of contaminated soil and wastewater through a combination of cutting-edge equipment, including the GNLW654-VFD Decanter Centrifuge.

- Details

-

Published: 10 January 2025

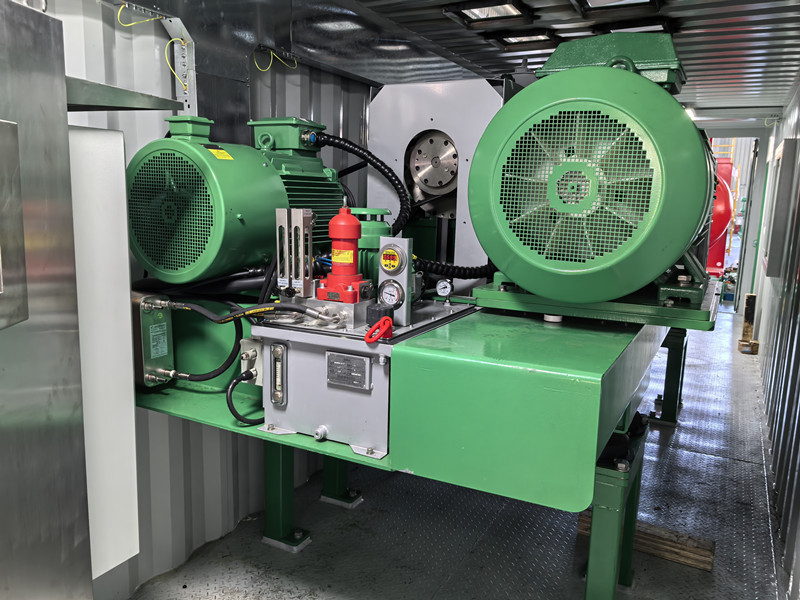

GN Containerized Sludge Dewatering Package for Soil Remediation, Packaged neatly within a standard 40ft container, the system boasts a comprehensive array of equipment tailored for exceptional mobility, straightforward installation, and robust functionality. At its core, the GNLW654-VFD sludge dewatering centrifuge, a powerhouse supplied by GN Separation and specifically tailored for this demanding application, stands out.

The GNLW654-VFD decanter centrifuge is furnished with a Variable Frequency Drive (VFD) control cabinet, a feature that offers operators unparalleled flexibility in adjusting the operational settings of the primary and secondary motors, feed pump, and polymer dosing pump. This capability allows for precise tuning of the system to accommodate varying feedstock attributes and optimize treatment efficiency, ultimately enhancing the quality of the dewatered sludge (or mud cake) while minimizing water content.

Acknowledging the severe abrasiveness of oil-tainted soil sludge, GN Separation has incorporated tungsten carbide plates and sleeves within the centrifuge's screw conveyor and slag discharge port. This strategic incorporation of wear-resistant materials not only safeguards vital components from premature wear and tear but also prolongs the overall lifespan of the equipment, thereby mitigating long-term maintenance expenses and fostering operational consistency. Complementing the centrifuge are a feed pump and dosing pump sourced from Netzsch, a reputable German manufacturer renowned for its dependable and high-performance industrial pumps. These components, integral to the system's seamless operation, guarantee precise and consistent delivery of both the sludge feed and flocculant chemicals crucial for enhancing solid-liquid separation.

The screw conveyor, another pivotal component, has been meticulously designed based on the system's intended throughput and the on-site configuration. This customized design not only facilitates smooth integration into the containerized setup but also ensures straightforward installation and user-friendly operation, which are crucial in remote and often logistically challenging environments akin to those in the Middle East.

- Details

-

Published: 10 January 2025

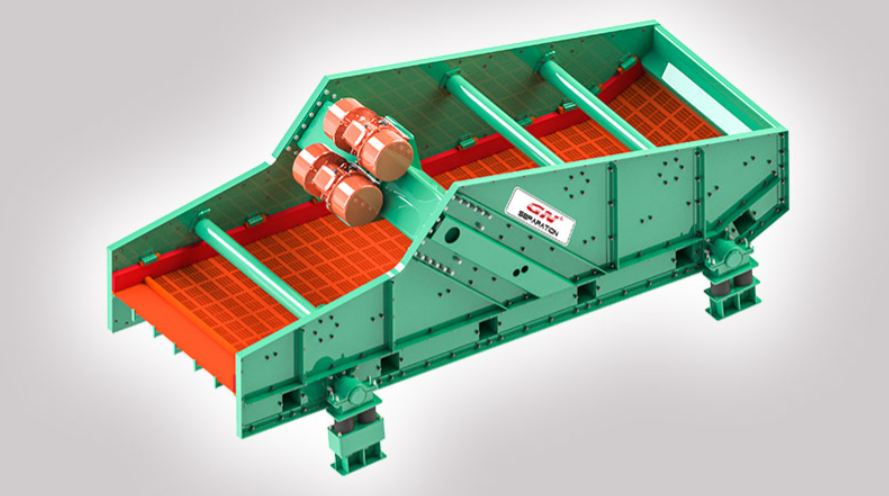

GN Separation Company has recently successfully completed the manufacturing and factory trial run of a new batch of Enhanced Frequency Vibrating Screens (SFVS). These advanced screening solutions will soon be dispatched to domestic coal chemical plants for project deployment.

Synergistic Frequency, Efficient Screening: The GNFK2030 adopts innovative synergistic frequency technology, achieving perfect resonance between the screening box and the material, significantly enhancing screening efficiency. This design not only accelerates the screening speed but also ensures screening accuracy, allowing fine particles to be easily separated, reducing material loss, and improving product quality.

Optimized Structure, Durable Performance: The equipment is made of high-strength, wear-resistant materials, combined with exquisite craftsmanship, ensuring a long service life. The optimized screen structure and vibration parameters enable the equipment to maintain stable performance while operating efficiently, reducing downtime for maintenance and lowering operational costs.

Intelligent Control, Flexible Adaptation: The GNFK2030 is equipped with an intelligent control system that can flexibly adjust vibration parameters based on material characteristics and screening requirements. This personalized screening solution allows the equipment to easily handle various complex screening tasks, meeting the diverse needs of coal chemical enterprises.

Low Noise, Environmentally Friendly, Comfortable Work Environment: We are well aware of the impact of noise on employee health and the work environment. Therefore, the GNFK2030 adopts advanced noise reduction technology, effectively reducing equipment operating noise and creating a more comfortable and healthy work environment for employees.

Modular Design, Easy Maintenance: The modular design of the equipment makes daily inspection and maintenance more convenient. This reduces maintenance difficulty and time costs, ensuring that the equipment can continue to operate efficiently and support enterprise production capacity upgrades.

GN Company has always been committed to providing customers with the highest quality products and services. The GNFK2030 Synergistic Frequency Vibrating Screen demonstrates its quality with strength and supports development with efficiency. Choose the GNFK2030 to inject powerful momentum into your coal chemical production line and create a brilliant future together!

- Details

-

Published: 05 January 2025

At GN Separation, we continuously innovate to deliver cutting-edge screening solutions for various industries. One of our flagship products, the GN Synergistic Frequency Vibrating Screen, has been deployed successfully in domestic coal chemical plants, providing exceptional performance and reliability. This blog explores the capabilities and advantages of our model GNFK2030, with a total of six units operating efficiently in coal processing facilities.

- Details

-

Published: 02 January 2025

At GN Separation, we understand the importance of high efficiency and low energy consumption in the processing industries. One of our standout products, the GN Dewatering Vibrating Screen, plays a pivotal role in addressing challenges related to tailings treatment, dewatering, and material separation across various industries, including mining, coal, construction materials, metallurgy, and chemicals. With its robust design and versatile functionality, this linear motion dewatering screen is a highly effective solution for dewatering, desliming, demineralization, and dry discharge of mining tailings.

- Details

-

Published: 26 December 2024